Offline lab tools designed to streamline QA processes.

QA Sample Testing

SpecMetrix®offline systems set a higher standard for non-contact, non-destructive film layer and coating QA analysis. Global companies in a wide range of industries use our technology as the preferred forensic tool based on its unmatched ability to identify and quantify thin coating or layer thickness defects with nanometric precision.

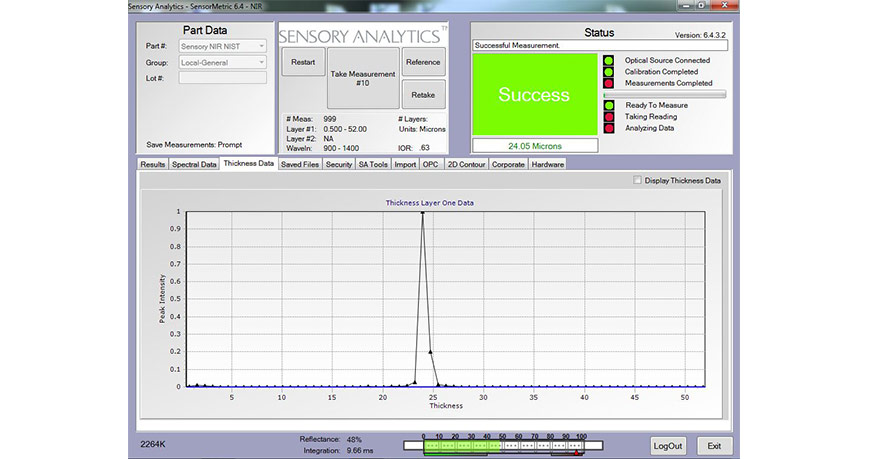

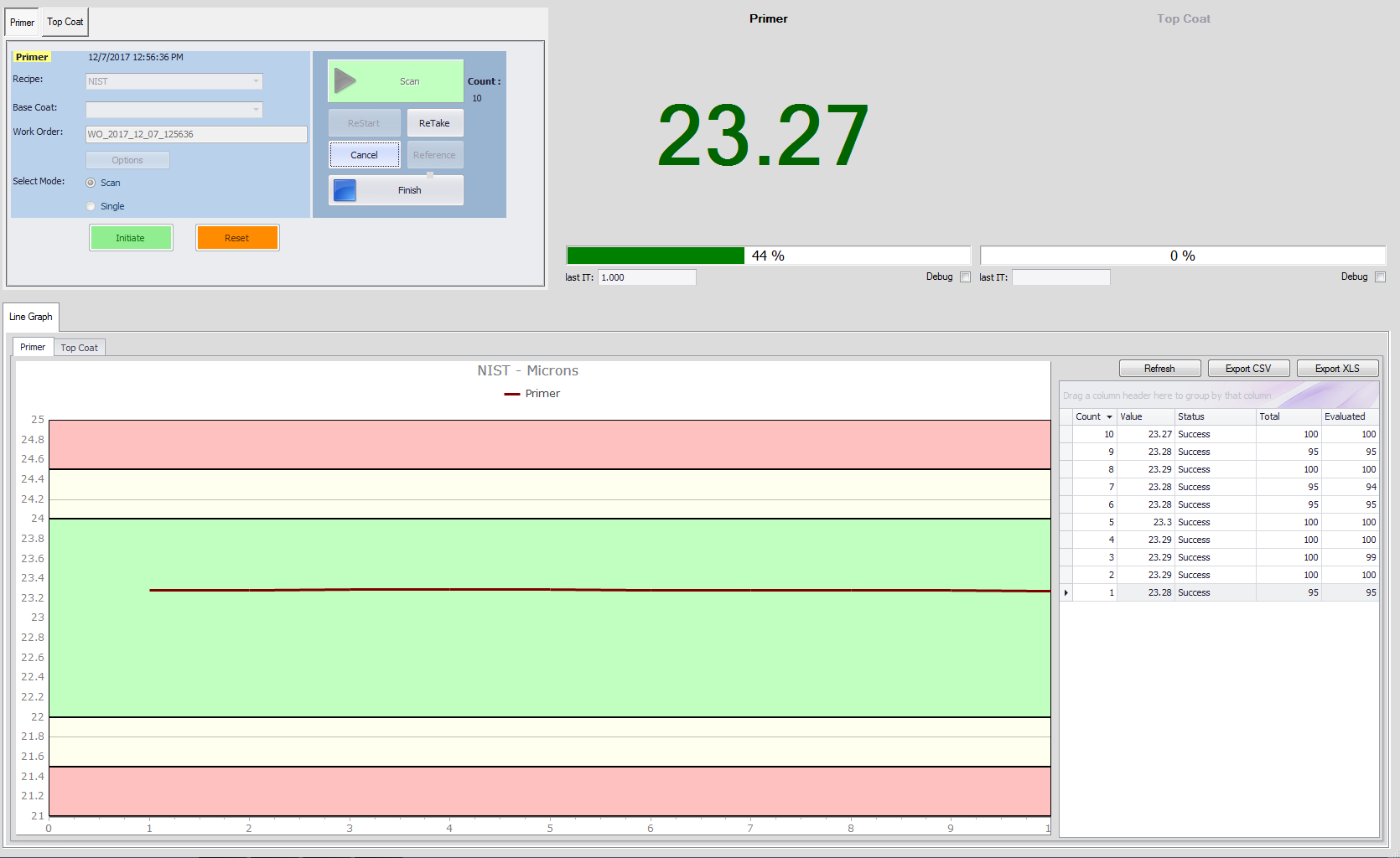

Our SpecMetrix lab systems can provide simultaneous thickness measurement of single or dual coatings or discrete film layers on flat samples and component parts in real-time. This ultra-precise and instant measurement capability accelerates sample testing data collection. All SpecMetrix offline configurations are measurement ready for wet or dry samples in any environment from the QA lab to the factory floor. This flexibility allows for easy and accurate coat weight and absolute thickness checks during set-ups or sample testing.

The lab system is easily transportable for ease of use between coating lines or work stations in a plant. Our off-line tools bring non-contact single point and scanned measurement directly to production and process team personnel. Our Enhanced Lab systems adds In-line measurement software along with one ruggedized probe to combine the benefit of off-line QA sample testing with In-line coating process validation capabilities. These capabilities optimize coating quality by improving inspections of coated sheet and coil strip samples.

Especially useful for:

> Pilot lines

> Test facilities

> High-changeover environments

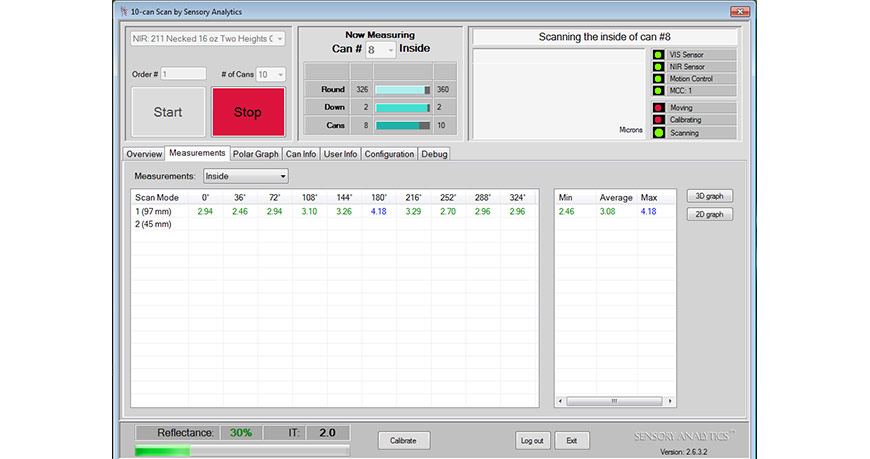

Our SpecMetrix lab systems featuring ACS accessories bring a new level of precision to container measurement. These systems are designed for the metal packaging industry, providing coating and film weight measurement and mapping of all internal and external container coatings. The complete range of thickness measurements tasks can be performed with ease within a lab, QA department, or directly on the production floor. Single can, 10-12 cans and automated configurations are all available to meet plant needs. ACS systems are modular and can be configured for use with multiple automation, conveying, scanning and process control tools.

Incoming QA Inspection

SpecMetrix systems provide the ultimate assurance that incoming QA inspection processes are reliable and effective for both base materials and coatings. Manufacturing a quality product starts with using quality materials and components. Substandard coatings or base material irregularities will be instantly detected by our non-contact, non-destructive ROI measurement technology.

Co-packing companies need exceptional accuracy to ensure their finished products include packaging coatings that fully comply with specifications. Our customers include many global leaders that use SpecMetrix systems within their QA and co-packing operations.

Finished Product Inspection

End product QA inspection reaches new standards of efficacy with SpecMetrix offline tools. Our ROI measurement technology is especially suited for finished product inspection on a wide range of products, dramatically improving coating QA and film layer analysis.

Our intuitive software interface makes QA analysis and sample testing much easier.For example, a drop-down menu can be easily configured to display a company’s full range of coatings; selecting a particular coating instantly loads relevant functionality. Data can also be displayed in multiple ways that meet user reporting needs. Mapping software with 2D and 3D graphs are also available for visual analysis of coating thickness and film weight distribution.

Our offline systems are easily upgraded.Our flexible, modular design makes reconfiguration easy, enabling future upgrade into SpecMetrix Enhanced lab or SpecMetrix In-line systems for more in-process use.

Used by global manufacturing leaders in a wide variety of industries.

Better data offers better protection from customer claims.Because our systems generate ultra-precise and absolute thickness data—and because that data is easily stored or exported to SPC systems—it is available to assist with quality assurance questions or claims. Quality claim analysis and film weight forensics have never been so accurate and reliable.

Savings in materials and labor add up quickly.Our offline lab systems quickly begin to prove their value by streamlining inspection times and reducing product waste and coating costs. Our customers report full ROI within an average of six to nine months along with an overall increase in finished product quality.

Want a closer look?

Request a password to login to our behind-the-scenes collection of demo videos, industry-specific information and specifications.

Measures coating thickness over any print or paint color on:

- Aluminum

- Steel

- Tinplate

- Galvalume

- Foils

- Primed paper

- Prints

- Plastics

- Films