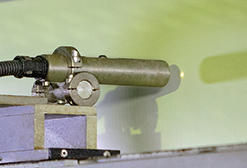

SpecMetrix® systems revolutionize coating thickness and film layer measurement.

Get precise thickness data in real time.

SpecMetrix technology delivers data on pilot production lines, flexible piece goods, and laminated web. Our exclusive ruggedized optical interference (ROI) technology provides absolute thickness measurement data in real time for fast response.

Measurements are absolute—and nanometrically accurate.

This precision is especially useful to measure thinner coatings and separate layers immediately following coating application in a pilot line or during full R2R web processing.

Process control saves at every step.

SpecMetrix systems allow you to streamline set-up, changeover and inspection times—resulting in cost savings that add up.

Wet or dry—SpecMetrix technology works on a wide variety of substrates.

Our non-contact systems precisely measure the wet or dry thickness of thin films and coatings—in-process or off-line—on a

wide variety of clear, opaque and printed substrates including films, foils, primed paper and plastics.

EXACT COATING THICKNESS and FILM WEIGHTS

✔ Coated webs

✔ Flat samples

✔ Film packages

✔ Monomer films

✔ Extrusions

✔ Finished film stacks

BROAD RANGE OF COATINGS

✔ Single and dual coatings

✔ UV coatings

✔ Silicones

✔ Barrier coatings

✔ Top coats

✔ Adhesives

✔ Scratch-resistant layers

✔ Other performance coatings

We serve companies in emerging roll-to-roll processing applications.

Hundreds of global leaders rely on SpecMetrix systems—in-process or offline—to improve process control and quality assurance. They consistently report that absolute in-process data yields a rapid return on investment within an average of six to nine months.

Want a closer look?

Request a password to login to our behind-the-scenes collection of demo videos, industry-specific information and specifications.

WHAT’S THE DIFFERENCE?

Traditional measurement tools

produce manual or inferential

weight readings that are less

precise. SpecMetrix systems

provide continuous real-time

absolute measurement data with

nanometric precision.