Our most advanced technologies serve the industry with the most exacting demands.

SpecMetrix® ROI technology is exceptionally suited to the stringent requirements of selected aerospace and defense applications. These industries present the widest range of coating and thickness measurement challenges, due to the diversity of applications and the wide variation in coatings and coating compositions.

Our expanding line of real-time coating thickness measurement solutions offer a more accurate, non-destructive means to measure coatings and surface finishes—on completed aircraft, vehicles and component parts:

Anodized layers

Anodized layers- Films and foils

- Glass

- Paints

- Top coat

- Protective finishes

- Primers

- Specialty coatings

We developed our SpecMetrix Dark systems to support advanced aerospace needs. These flexible tools employ alternate non-contact RFE technologies to measure opaque specialty and performance materials, and to identify defects in composite materials in the QA lab, in the spray booth, on the manufacturing line or at repair depots. Combined RFE and ROI technology systems are also available to meet diverse customer needs.

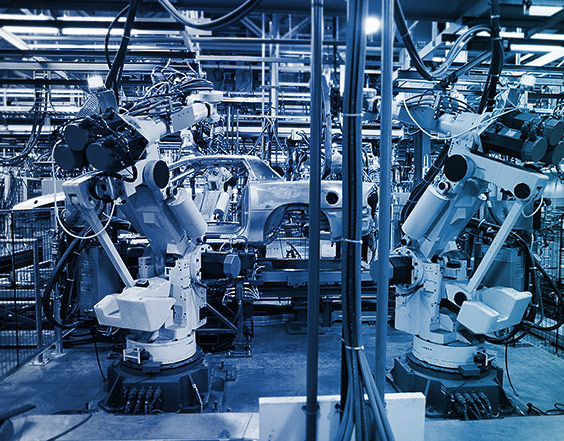

Providing maximum flexibility, SpecMetrix systems are available as stand-alone units, rack mounted assemblies or can be integrated to various automation options, including robotic spray systems for measuring wet or dry coatings and aircraft finishes immediately following application.

Our coating thickness gauges help improve the spray and finishing QA procedures and minimize coating inspection and sanding man hours. The result is a more efficient, more profitable production process. Our customers report full ROI within an average of six to nine months.

Want a closer look?

Request a password to login to our behind-the-scenes collection of demo videos, industry-specific information and specifications.

QA data delivered in real time.

- Non-destructive coating thickness and QA method

- Automatic data capture and storage for SPC

- Measures thicker coatings over varied substrates

- User-friendly and easy to add new coating recipes

- 2-D and 3-D mapping options for distribution and QA review

Anodized layers

Anodized layers